Tecnología

- Stanton stitched welt construction

-

Existen dos métodos conversacionales para la fabricación de calzado:

- Pegar la suela a la parte superior del zapato.

- Coser la suela a la parte superior del zapato.

Como ninguno de estos métodos es totalmente confiable por sí solo, el equipo de investigación y desarrollo en Stanton S.A.S. patentó un método revolucionario mediante el cual la suela y la parte superior del zapato se unen tanto con adhesivos como con costuras, para superar así las carencias de los dos métodos y aprovechar las ventajas de cada uno. el resultado es el calzado Stanton stitched welt construction.

Brahma es una de las pocas compañías selectas que tienen licencia para utilizar esta extraordinaria tecnología para sus productos.

- Stitched cup-sole construction

-

Brahma emplea esta exclusiva y no convencional metodología de fabricación para sus productos. la suela de los zapatos es diseñada a manera de copa, de modo que el zapato encaja perfectamente en la suela, se pega y posteriormente es cosida de lo largo del contorno de la suela.

- Fibras y tecnologías especiales

-

Absortex y Total Dry son materiales utilizados para forros de calzado que gozan de patentes internacionales y fueron desarrolladas para cumplir las requerimientos de beneficios y calidad más exigentes en la industria del calzado.

- Absorbtex

-

Diseñado para una máxima comodidad y protección

- Absorbe la transpiración.

- Seca rápido.

- Mantiene la suavidad para proporcionar comodidad adicional.

- Resistente a hongos y malos olores.

- Ofrece doble acción de control de temperatura (refresca cuando hay calor y calienta cuando hace frío).

- Tiene ventajas de ventilación que aprovecha los beneficios del cuero y compensa cuando es usado con materiales sintéticos no respirables.

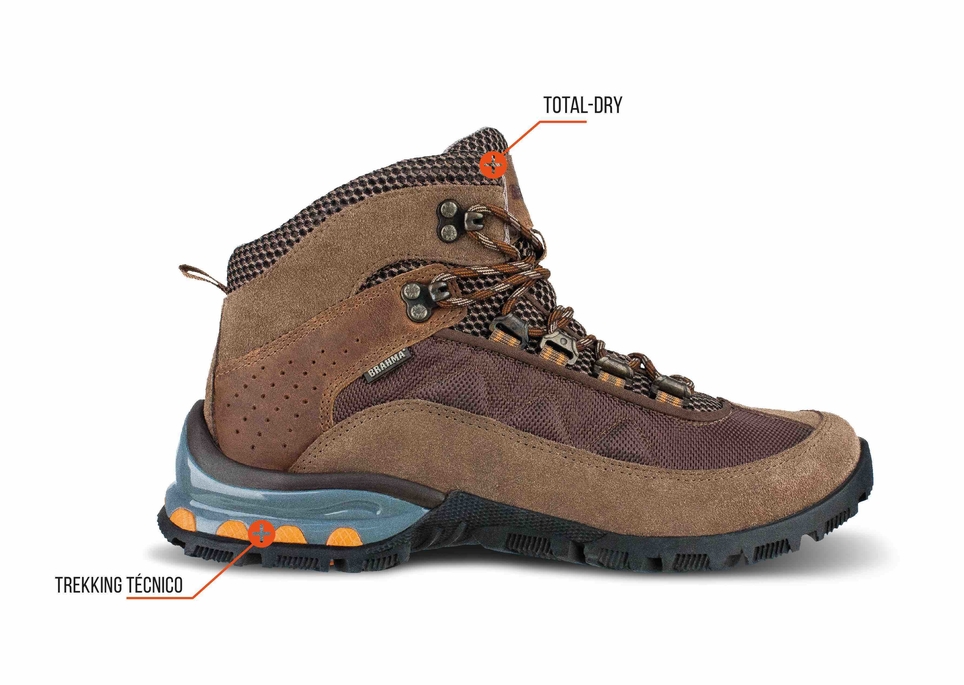

- Total Dry

-

Compartimiento de aire fresco, mantiene los pies cómodos y secos con su exclusivo sistema de transferencia de humedad.

- Es un material de tres capas entretejidas que crean compartimentos de aire y permiten una óptima ventilación de los pies.

- La construcción del triple tejido provee múltiples beneficios gracias a su construcción con fibras de nylon entrecruzadas.

- Las propiedades de absorción aíslan la humedad de la piel manteniendo los pies secos y frescos.

- Su avanzada tecnología asegura comodidad excepcional y un perfecto balance de la temperatura.

- Durafoam

-

Caminando en las nubes, un nuevo concepto que revoluciona la comodidad, en comparación con las plantillas tradicionales, la tecnología durafoam reduce el cansancio de los pies superando las más altas exceptivas.

- Reduce el riesgo de lesiones en las pies producto de actividad excesiva, transpiración, contacto con superficies duras y el peso corporal.

- Ayuda a eliminar el cansancio en lo pies al disminuir el esfuerzo muscular.

- Diseñadas para ofrecer ajuste preciso a la forma del pie.

- Crea pequeñas corrientes de aire con cada paso, las cuales ventilan el pie y ayudan a absorber los impactos para comodidad adicional.

- Forrado con absortex para mayores beneficios en comodidad.

- Phylon

-

Todas las propiedades de máxima calidad en un material ultraliviano. Mientras la industria de calzado se esfuerza por utilizar materiales de bajo peso, los productos Brahma ya cuentan con la tecnología y los materiales de vanguardia.

- Extraordinarios propiedades de flexión y absorción de impactos en una densidad de tan solo 0.20 g/cm3.

- Cuenta con ventajas de elasticidad y resistencia, que a su vez permiten el desarrollo de un calzado con diseños más elaborados.

- Aunque todas las ventajas se encuentran fuera de la vista en el producto terminado, se sienten y son verdaderamente importantes al momento de usarlo.

- Celstan

-

Suelas ultralivianas,

- 30% menos peso puede traducirse en 300% más agilidad

- Un calzado más liviano que conserva todas sus propiedades técnicas y de calidad.

- Mayor amortiguación.

- Cámaras de aire imperceptibles en el interior, con su superficie de película externa gruesa y resistente.

- Plantillas anatómicas

-

- Una plantilla con la forma anatómica del pie.

- Forrada con una gama de materiales que ayudan a absorber la transpiración.

- Removibles para que puedan ser lavadas y secadas de manera práctica, al mismo tiempo que permiten al zapato mantenerse fresco.

- Ayuda a evitar moho y malos olores.